How Single Skin Panels Prevent Thermal Bypass in Building Envelopes

In current building, power saving and user ease are main goals. But these aims can be hurt by secret flaws in the outer shell. One of the most key is heat skip. Knowing how to stop this event is vital for making top-working structures. One good fix lies in the use of single skin panels. They give both design charm and useful gains.

What Is Thermal Bypass and Why Does It Matter in Building Performance?

Before looking at how single skin panels add to air stop setups, it's key to know what heat skip is. And why it causes a trouble.

The Definition and Mechanisms of Thermal Bypass

Heat skip means the unwanted shift of air. This air often carries warmth or damp. It goes through spaces, breaks, or badly closed links in an outer shell. Unlike straight flow through stuff, heat skip lets warmth move via air flow. It weakens padding work even when padding is put in right.

Impacts of Thermal Bypass on Energy Efficiency and Comfort

This event can greatly cut power saving. It does this by letting treated air go out or untreated air come in the setup. So, heating and cooling units must run harder to keep warmth levels. This raises power bills. It also causes uneven inside warmth. And possible damp troubles that can hurt user ease and structure strength.

Common Areas Where Thermal Bypass Occurs in Building Envelopes

Heat skip usually happens around glass openings, entrances, links between wall groups, top-wall meets, and holes for tubes or power lines. These weak spots must be handled with care during plan and build.

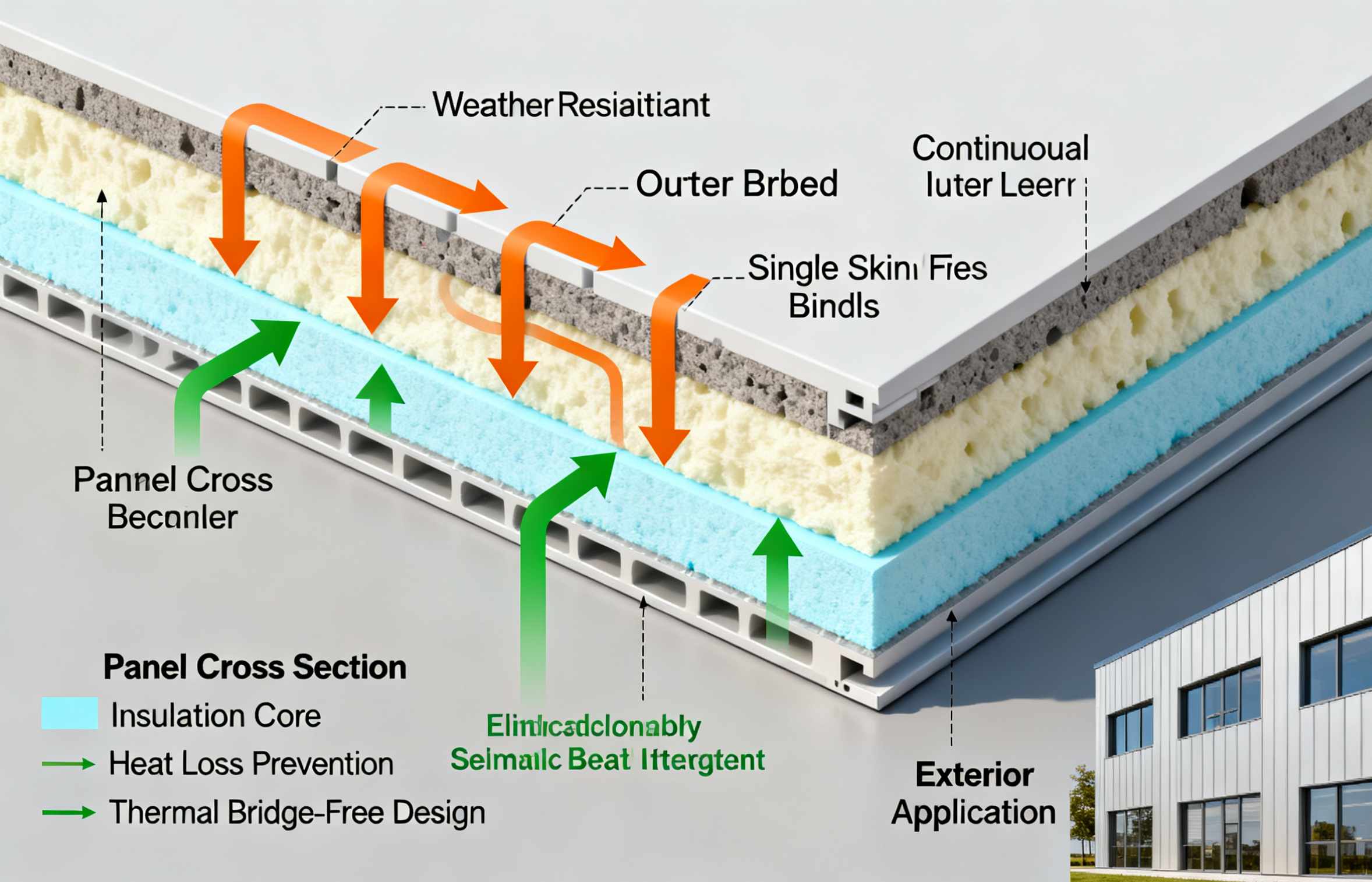

Single skin profile panels are outside covering setups made of one sheet of metal. This can be iron mix, light metal, red metal, or gray metal. It is formed into a certain shape.

How Do Single Skin Panels Contribute to a Continuous Air Barrier?

To fight heat skip well, structures need a steady air stop setup. Single skin panels play a big part in this guard way.

The Role of Air Barriers in Preventing Heat Loss

Air stops are planned to manage the shift of air into and out of the outer shell. By cutting uncontrolled air flow, they help keep treated air inside. At the same time, they hold outside parts out. This boosts warmth work and cuts power use.

Characteristics of Single Skin Panels That Support Air Sealing

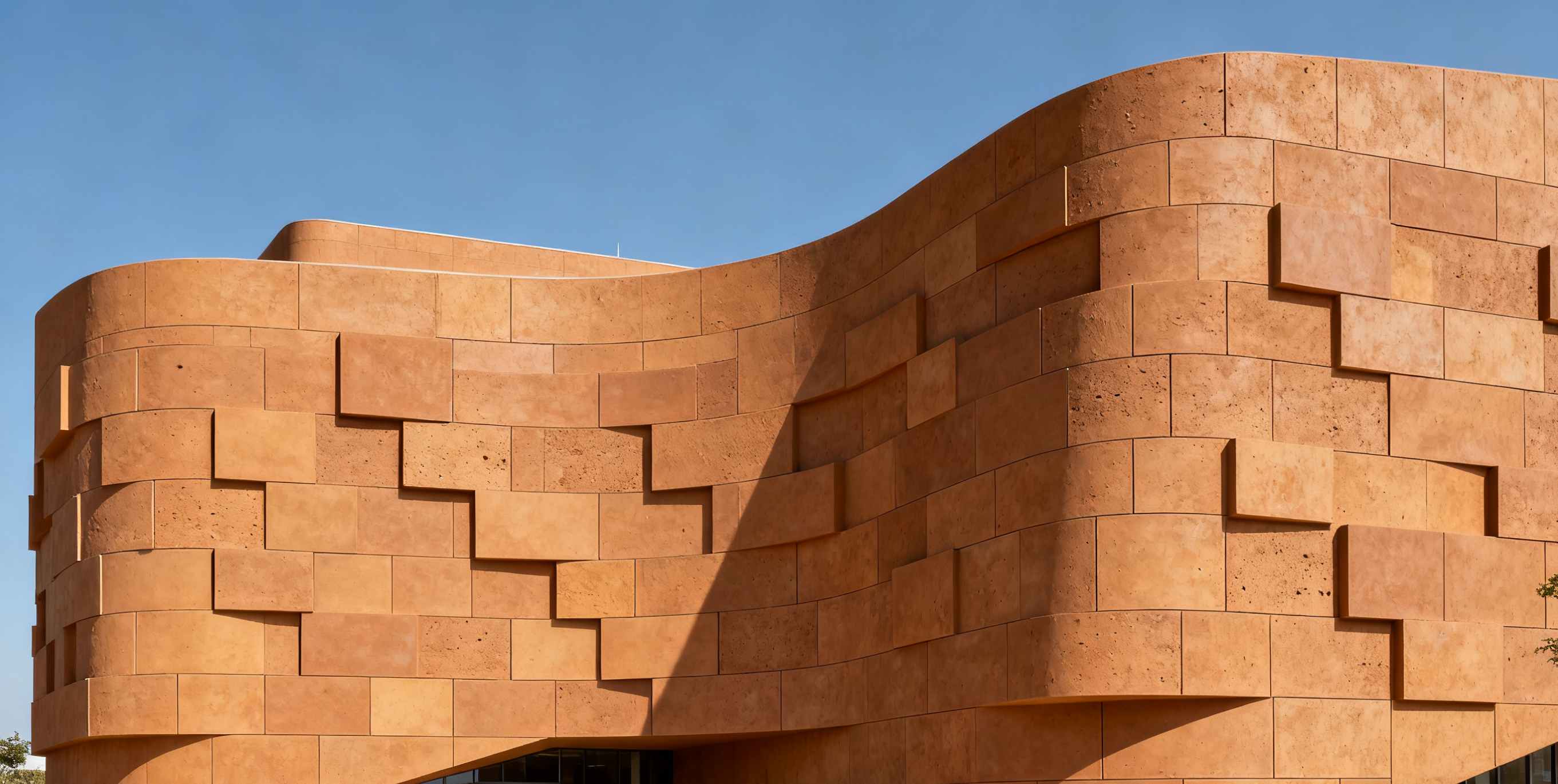

Single skin profile panels are known for their toughness and weather fight. They give long-lasting guard for structure outsides. Their smooth surface cuts links where air leak could happen. Their mix of power and low weight makes them perfect for big jobs. This helps cut the load on the frame.

Integration of Single Skin Panels into Envelope Design

Single skin profile panels are very flexible. They can fit into many design styles and structure uses. This includes tops, outside walls, undersides, upper covers, inside walls, and tool shields. When mixed with right closing ways during put in, they add to a tight outer shell. This backs steady air stop plans.

Tuodeli knows these troubles well. By giving single skin profile panels that are simple to put in with few spaces and flexible across different uses, Tuodeli aids planners keep tightness through the shell.

Why Are Single Skin Panels Effective at Reducing Thermal Bridging?

While linked to heat skip, heat link is a different trouble that single skin panels also help lessen.

Differences Between Thermal Bridging and Thermal Bypass

Heat link happens when warmth goes through more leading stuff. This can be metal holders or frames that break padding layers. Unlike heat skip which involves air flow, heat link is fully leading. But it is just as harmful to power saving.

Material Properties That Minimize Heat Transfer

Single skin profile panels are handled with guard layers that help stop rust and color loss. These also boost their skill to keep steady work over time without wear that might raise leading.

Panel Design Features That Limit Bridging Paths

Their even or shaped plan lets them cover big spots with fewer frame breaks. By using our advanced plate roller, we can form Single skin profile panels into various shapes. This raises the look charm of your setup. This bend helps cut need on under-frame setups. Those often bring in heat links.

Tuodeli handles this sore spot by making panel shapes that cut touch spots with frame parts. At the same time, they keep setup wholeness. This well limits leading warmth paths across the shell.

In What Ways Do Installation Methods Influence Performance?

Even the top stuff can do poorly if not put in right. Good put in makes sure single skin panels give on their promise for tightness and power saves.

Importance of Proper Sealing and Fastening Techniques

Pads, closers, strips, and even holder kinds all affect if a group stays tight over time. Bad closing can make spaces that hurt both air stop steadiness and water fight.

Avoiding Gaps and Discontinuities During Installation

Care during panel line up is vital. Wrong lined or loose fit panels may leave tiny openings. These let air flow or damp come in. This beats the aim of using top-working covering setups like single skin panels.

Quality Control Measures for Long-Term Integrity

Regular checks during build make sure steady closing ways across all links. After put in tests like wind door checks confirm if wanted work levels have been reached.

Tuodeli backs workers with full put in guides made for each panel kind. This ensures best outcomes even under short job times. And it gives grade promise steps lined with top ways in current build.

Who Is Tuodeli and What Makes Their Products Stand Out?

Tuodeli has set itself as a top in top-working face fixes by mixing skill know with plan new ideas.

Overview of Tuodeli's Expertise in Single Skin Wall Panels

With deep know making single skin profile panels from various metals like light metal or gray metal, Tuodeli gives changeable choices fit for work buildings as well as business or home uses.

Commitment to Innovation, Quality, and Energy Efficiency

From advanced shaping tools to rust-fight layers, Tuodeli's fixes mix looks with use. Their push on lasting making lines well with green build aims such as green cert help.

What Are the Long-Term Benefits of Using Single Skin Panels?

Beyond start work gains during build step, single skin profile panels give many gains for structure faces over their life.

Enhanced Thermal Performance Over Time

Thanks to their tough ends, these panels keep their look over time without bend or wear. This is a main thing in keeping steady air stops year after year.

Reduced Operational Costs and Maintenance Needs

Their straight put in and quick group help lower build costs. While long-lasting fight against weather cuts upkeep bills a lot over years.

Contribution to Sustainable Building Certifications

Also, their high reuse makes them a nature kind choice for build jobs. This sets them as perfect parts in jobs aiming certs like green or health build rule.

Conclusion

As structures get more hard and hopes around power work keep going up, the value of managing heat skip cannot be said too much. Single skin panels give a nice yet real fix by backing tightness. At the same time, they cut both heat link and long-lasting upkeep loads. With shown skill from makers like Tuodeli behind them, single skin profile panels stand out as vital tools in today's top-working design kit.

FAQs

Q1: How do single skin panels differ from insulated panels?

A: Insulated metal panels feature built-in insulation layers between two metal sheets; single skin panels consist only of one metal sheet without integrated insulation but can be combined with other materials for enhanced performance benefits.

Q2: Can single skin panels be used in both new construction and retrofits?

A: Yes. They are highly versatile and suitable for both new builds as well as renovation projects due to their lightweight nature and flexible mounting options. They support both vertical and horizontal installation, making them adaptable across various retrofit scenarios too.

Q3: Do single skin panels require specialized maintenance?

A: No. They are treated with protective coatings that help prevent corrosion, reducing maintenance needs significantly compared to traditional cladding systems while preserving aesthetic appeal over time.